V-Carving

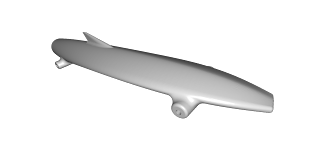

Back a few years ago I did a speed comparison on a few CAM programs for generating g-code for cnc machines. Since then I have done a lot of machining using those programs, but also some work with a program called f-engrave. f-engrave is a python program that produces tool path for a machining process called v-carving, and well as general engraving.V-carving, as seen above, is a process that produces 3D carved features in a work piece using a tapered bit. V-carving is often used for 3D carved signs and is especially popular for carving block lettering. V-carving produces high quality engravings with greatly reduced cutting time in comparison to 3d contouring, however, it is generally limited to features that have relatively narrow strokes. The width of the stroke is determined by the depth of the cut using a v-shaped bit.

Vetric's VCarve software is a popular software suite for producing tool paths for v-carving. VCarve Pro isn't as expensive as some CAM software, but I can't justify the purchase price for hobby use. There are a few other commercial software suites for producing v-carving tool paths, but the prices are similarly aimed at commercial sign makers and the like ($500-$5000).

F-Engrave

So, some time ago I started using the v-carving features of f-engrave to make some Christmas gifts. As far as I'm concerned, f-engrave does a great job producing tool paths. I found that the most useful workflow for producing high quality engravings was to create a black and white image of the project in a graphics application like Inkscape or Adobe Illustrator, convert to a bitmap, and import into f-engrave. f-engrave uses a bitmap to vector conversion tool called potrace.Potrace does a pretty good job converting the bitmap to a vector. However, if you have done much work converting bitmaps to vectors you will know that without the right resolution bitmap and the right settings in the convertor you can end up with one of two problems. First, if you start of with two low of a resolution bitmap, then you end up with a jagged vector image. Second, if you have too of a high resolution bitmap and the wrong setting in the converter then you end up with a vector representation with hundreds of thousands of line segments.

In f-engrave (up to version 1.36) if you have a vector image that has many line segments the v-carving calculations begin to take a long time. For example, an unoptimized vector image could take my relatively speedy intel i7 machine 30 minutes+ to calculate the v-carving. However, it I take the time to tune the resolution of the image and the potrace setting f-engrave would only take about 5 minutes to do the same job. This became a bit of a frustration as I would find myself spending and hour or more to get the settings right so the image caved well, but didn't take forever to calculate.

I should explain that it is possible to import a vector image as a dxf directly, but the many different versions of dxf formats makes this difficult. Besides, how many good graphics programs produce good dxf files without significant effort. I decided that what I needed was the ability to import any old bitmap image even a high resolution and not have to wait forever for the tool paths to be calculated.

I knew that f-engrave used a somewhat brute force algorithm, but I wondered how much faster it would run it I were to re-write the code in C++ or java. Thankfully, I didn't take the time to rewrite the code in c++. I'm sure that it is true that the algorithms as they existed would run faster in c or c++ than they did in python, but often a change in the algorithm will make a much for significant difference.

Due to the fact that f-engrave is a single file python program it is really easy to dive in and see how the program works. I love this as it was fairly simple for a weekend warrior programmer like myself to modify the program and implement some improvements. I was able find a chunk of the code that was taking a large portion of the computation time that was in a recursive loop and came up with a way to do some pre-processing to eliminate the need for most of it. This lead to a huge increase in the speed of the program. Below you can see the speed improvement from the change:

Unfortunately, it took me about a year to remember that I needed to get this code back to the developer of f-engrave for the community to get the improvement. I recently did that and hopefully in the coming weeks a new version of f-engrave will be released with this improvement.

The result with the speed improvement is that I can now import a high resolution bitmap image from whatever tool I used to create it and get a high quality toolpath out of f-engrave quickly. I'm happy, and I hope that many of you who read with will be happy about it too.